In contrast to historically printed circuit boards, that are flat, 3D circuitry permits parts to be stacked and built-in vertically—dramatically decreasing the footprint required for units.

Advancing the frontiers of 3D printed circuits, a workforce of researchers from the Nationwide College of Singapore (NUS) has developed a state-of-the-art approach—referred to as tension-driven CHARM3D—to manufacture three-dimensional (3D), self-healing digital circuits. This new approach permits the 3D printing of free-standing metallic buildings with out requiring help supplies and exterior strain.

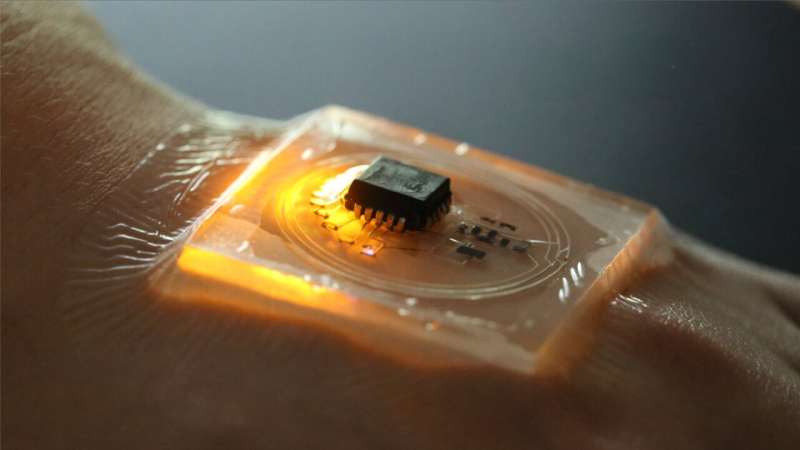

The analysis workforce led by Affiliate Professor Benjamin Tee from the Division of Supplies Science and Engineering within the NUS Faculty of Design and Engineering used Subject’s metallic to reveal how CHARM3D can fabricate a variety of electronics, permitting for extra compact designs in units similar to wearable sensors, wi-fi communication techniques and electromagnetic metamaterials.

In well being care, as an example, CHARM3D facilitates the event of contactless very important signal monitoring units—enhancing affected person consolation whereas enabling steady monitoring. In sign sensing, it optimizes the efficiency of 3D antennas, resulting in improved communication techniques, extra correct medical imaging and strong safety purposes.

The workforce’s findings had been printed within the journal Nature Electronics on 25 July 2024. Assoc Prof Tee is the corresponding creator of the analysis paper.

A extra streamlined strategy to 3D circuit manufacturing

3D digital circuits more and more underpin fashionable electronics, from battery know-how to robotics to sensors, enhancing their functionalities whereas enabling additional miniaturization. For instance, 3D architectures, with their giant efficient floor areas, enhance battery capability and improve sensor sensitivity.

Direct ink writing (DIW), a promising 3D printing approach at the moment used to manufacture 3D circuits, poses important drawbacks. The crux lies in its use of composite inks, which have low electrical conductivity and entail help supplies to help in solidification after printing. The inks are additionally too viscous, limiting printing pace.

Enter Subject’s metallic, an eutectic alloy of indium, bismuth and tin. Eutectic alloys soften and freeze at a single temperature decrease than the melting factors of their constituent metals—providing a horny different materials for 3D printing. With a low melting level of 62°C, a excessive electrical conductivity and low toxicity, Subject’s metallic, not like composite inks, solidifies quickly—an important attribute that permits the printing course of to eschew help supplies and exterior strain.

Leveraging the low melting level of Subject’s metallic, the CHARM3D approach exploits the strain between molten metallic in a nozzle and the vanguard of the printed half, culminating in uniform, easy microwire buildings with adjustable widths of 100 to 300 microns, roughly the width of 1 to 3 strands of human hair. Critically, phenomena similar to beading and uneven surfaces—attribute of pressure-driven DIW—are additionally absent in CHARM3D.

In comparison with standard DIW, CHARM3D gives sooner printing speeds of as much as 100 millimeters per second and better resolutions, providing a larger stage of element and accuracy in circuit fabrication. CHARM3D forgoes post-treatment steps and permits the fabrication of complicated free-standing 3D buildings, similar to vertical letters, cubic frameworks and scalable helixes. Furthermore, these 3D architectures exhibit wonderful structural retention with self-healing capabilities, that means they’ll routinely get better from mechanical injury and are recyclable.

“By providing a sooner and easier strategy to 3D metallic printing as an answer for superior digital circuit manufacturing, CHARM3D holds immense promise for the industrial-scale manufacturing and widespread adoption of intricate 3D digital circuits,” stated Assoc Prof Tee.

Far-reaching purposes

The researchers efficiently printed a 3D circuit for wearable battery-free temperature sensors, antennas for wi-fi very important signal monitoring and metamaterials for electromagnetic wave manipulation—capturing the variety of purposes enabled by CHARM3D.

Conventional hospital tools similar to electrocardiograms and pulse oximeters require pores and skin contact, which may trigger discomfort and danger infections. By means of CHARM3D, contact-free sensors will be built-in into sensible clothes and antennas, offering steady, correct well being monitoring in hospitals, assisted-living services or residence settings.

Moreover, arrays of 3D antennas or electromagnetic metamaterial sensors—fabricated by way of CHARM3D—might optimize sign sensing and processing purposes. This results in improved signal-to-noise ratios and better bandwidths. The approach opens up the potential of creating specialised antennas for focused communication, enabling extra correct medical imaging, similar to microwave breast imaging for early tumor detection, and superior safety purposes, similar to detecting hidden units or contraband emitting particular electromagnetic signatures.

Different collaborators on this work embody Dr. Zhuangjian Liu from Company for Science, Know-how and Analysis’s Institute of Excessive Efficiency Computing and Professor Michael Dickey from North Carolina State College’s Division of Chemical and Biomolecular Engineering.

Subsequent steps

The analysis workforce envisions that this method will be prolonged to different kinds of metals and structural purposes. The workforce can be on the lookout for alternatives to commercialize this distinctive strategy to metallic printing.